advertisement

Understanding the Benefits of a Centrifugal Pump

A centrifugal pump is a useful device which utilizes a rotating impeller to move liquids and gases in a variety of industries. This type of pump is popular because of its efficiency and cost-effectiveness compared to other pumps. In this article, we will look at the various advantages of using a centrifugal pump, including its durability, reliability, versatility, and cost-effectiveness, as well as the common applications for this type of pump and the steps to take when selecting one for your needs.

advertisement

What is a Centrifugal Pump?

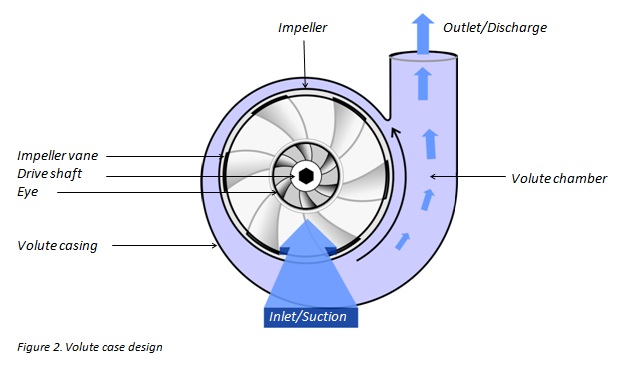

A centrifugal pump is typically used to move liquids, but can also be used to move gases. It consists of an impeller which is connected to a drive motor that spins the impeller at high speed. When the impeller spins, it creates a centrifugal force which causes fluid to move around the pump’s casing. The fluid is then discharged at a higher pressure than it was when it entered the pump.

Centrifugal pumps are used in a variety of applications, from industrial processes to water supply systems. They are also used in the oil and gas industry, as well as in the medical field for pumping blood. Centrifugal pumps are highly efficient and reliable, making them a popular choice for many applications.

How Does a Centrifugal Pump Work?

The impeller is the key component of a centrifugal pump, as it is responsible for spinning the liquid or gas around the casing. When the impeller spins, it creates a vacuum which sucks the fluid or gas into the pump. As the impeller continues to spin, it increases the pressure on the fluid, which forces it out of the pump at a higher pressure than it entered with.

The impeller is usually powered by an electric motor, although some pumps are powered by a gasoline engine. The impeller is connected to the motor via a shaft, which is responsible for transferring the power from the motor to the impeller. The impeller is designed to spin at a high speed, which is necessary to create the pressure needed to move the fluid or gas through the pump.

advertisement

Advantages of Using a Centrifugal Pump

Using a centrifugal pump has many advantages over other types of pumps. One of the main benefits of using this type of pump is that it is highly efficient, as it does not require a large amount of energy to operate. Additionally, centrifugal pumps are relatively simple to maintain and can be used in a wide range of applications.

Centrifugal pumps are also capable of handling a wide range of liquids, including those with high viscosity. This makes them ideal for applications such as oil and gas production, as well as for pumping water in industrial settings. Furthermore, centrifugal pumps are relatively inexpensive compared to other types of pumps, making them a cost-effective solution for many applications.

Cost-Effectiveness of Centrifugal Pumps

One of the main advantages of using a centrifugal pump is its cost-effectiveness. Due to their efficient operation and low maintenance requirements, centrifugal pumps are often much less expensive than other types of pumps. Additionally, due to their relatively simple construction and operation, centrifugal pumps are generally easier to install than other types of pumps.

In addition to their cost-effectiveness, centrifugal pumps are also highly reliable and durable. They are designed to withstand a wide range of operating conditions and can be used in a variety of applications. Furthermore, centrifugal pumps are often more energy efficient than other types of pumps, making them an ideal choice for many industrial and commercial applications.

Durability and Reliability of Centrifugal Pumps

Centrifugal pumps are also known for their durability and reliability. This type of pump is designed to withstand high pressures and temperatures, making them suitable for use in harsh environments. Additionally, centrifugal pumps are often capable of running continuously without needing to be shut off or paused, making them more reliable than other types of pumps.

Centrifugal pumps are also easy to maintain and repair, as they have fewer moving parts than other types of pumps. This makes them a cost-effective choice for many industrial and commercial applications. Furthermore, centrifugal pumps are often designed to be energy efficient, helping to reduce operational costs.

Versatility of Centrifugal Pumps

The versatility of centrifugal pumps is another advantage that makes them popular in many industries. Centrifugal pumps can be used for a wide range of applications, from transferring liquids in industrial plants to providing water for irrigation systems. They can also be used to move gas or steam in some cases.

Centrifugal pumps are also known for their durability and reliability. They are designed to withstand harsh conditions and can be used in a variety of environments. Additionally, centrifugal pumps are relatively easy to maintain and can be serviced quickly and efficiently.

advertisement

Common Applications for Centrifugal Pumps

Centrifugal pumps are used for many different applications in both residential and commercial settings. Some common applications include transferring water from a well to a home or business, providing water for swimming pools and hot tubs, transferring oil and chemicals in industrial settings, and boosting water pressure in municipal water systems. Centrifugal pumps are also commonly used in irrigation systems.

In addition, centrifugal pumps are used in many other applications, such as providing water for firefighting, cooling systems, and water treatment plants. They are also used in the food and beverage industry for transferring liquids, such as milk, juice, and beer. Centrifugal pumps are also used in the medical field for transferring blood and other fluids.

Choosing the Right Centrifugal Pump for Your Needs

When selecting a centrifugal pump for your needs, it’s important to consider the size and capacity of the pump as well as the application you’ll be using it for. Additionally, you should research different types of pumps to determine which one will be best suited to your needs. Additionally, consider any additional features that may be necessary such as a pressure switch or anti-siphon valve.

It is also important to consider the cost of the pump and any associated installation costs. Additionally, you should research the manufacturer to ensure that they have a good reputation and provide quality products. Finally, make sure to read reviews from other customers to get an idea of how the pump performs in real-world applications.

Maintenance and Care for Your Centrifugal Pump

Centrifugal pumps require minimal maintenance and care. Generally, all that’s needed for routine maintenance is regular cleaning and checking for any signs of wear or damage. Additionally, it’s important to regularly check that the pump is performing at its optimal level and adjust accordingly.

In conclusion, centrifugal pumps are highly efficient and cost-effective devices that are suitable for a wide range of applications. They are durable and reliable and require minimal maintenance and care. When selecting a centrifugal pump for your needs, consider its size and capacity as well as any additional features you may need. With proper care and maintenance, your centrifugal pump will provide you with years of reliable service.

advertisement

Post a Comment